CNC () machining is a versatile manufacturing technology that has revolutionized various industries. From automotive to aerospace, different industries have integrated CNC machining into their manufacturing processes to enhance productivity and achieve high-quality results. As your North American CNC machine manufacturer, Fadal would be more than happy to help you discover the benefits of CNC machining for your industry.

Here’s how different industries use CNC machines to drive innovation and meet their specific needs.

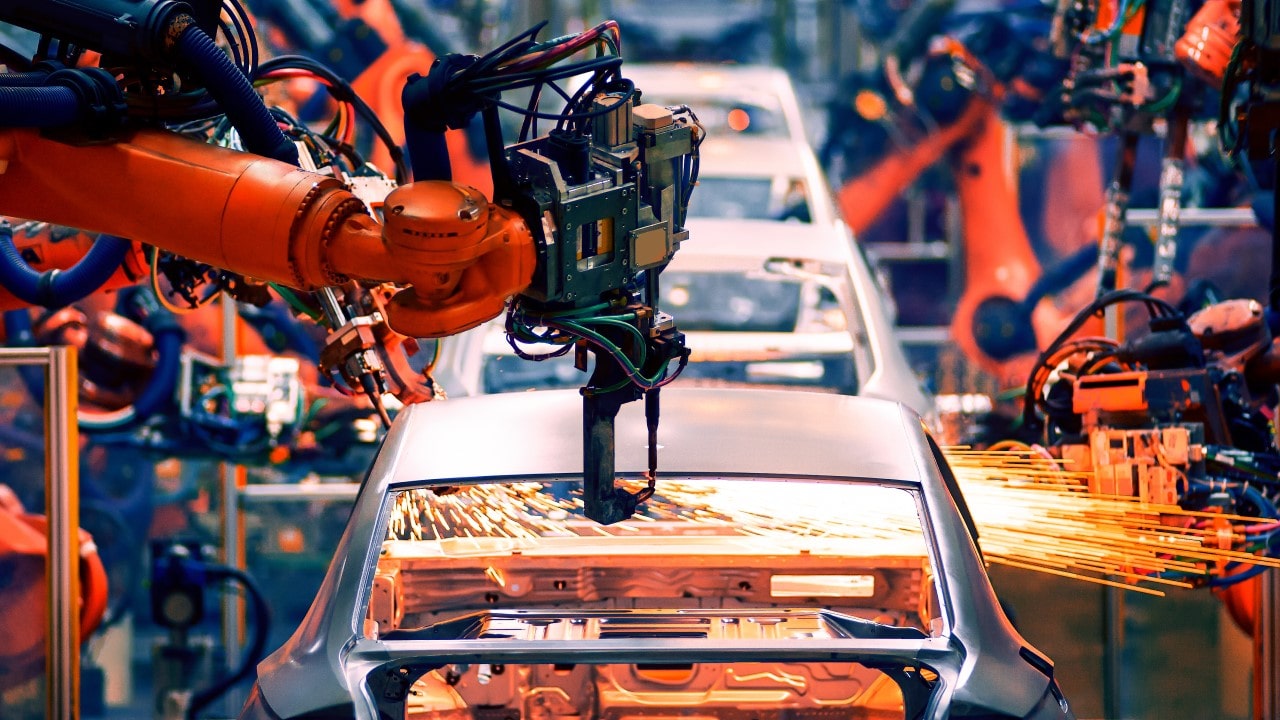

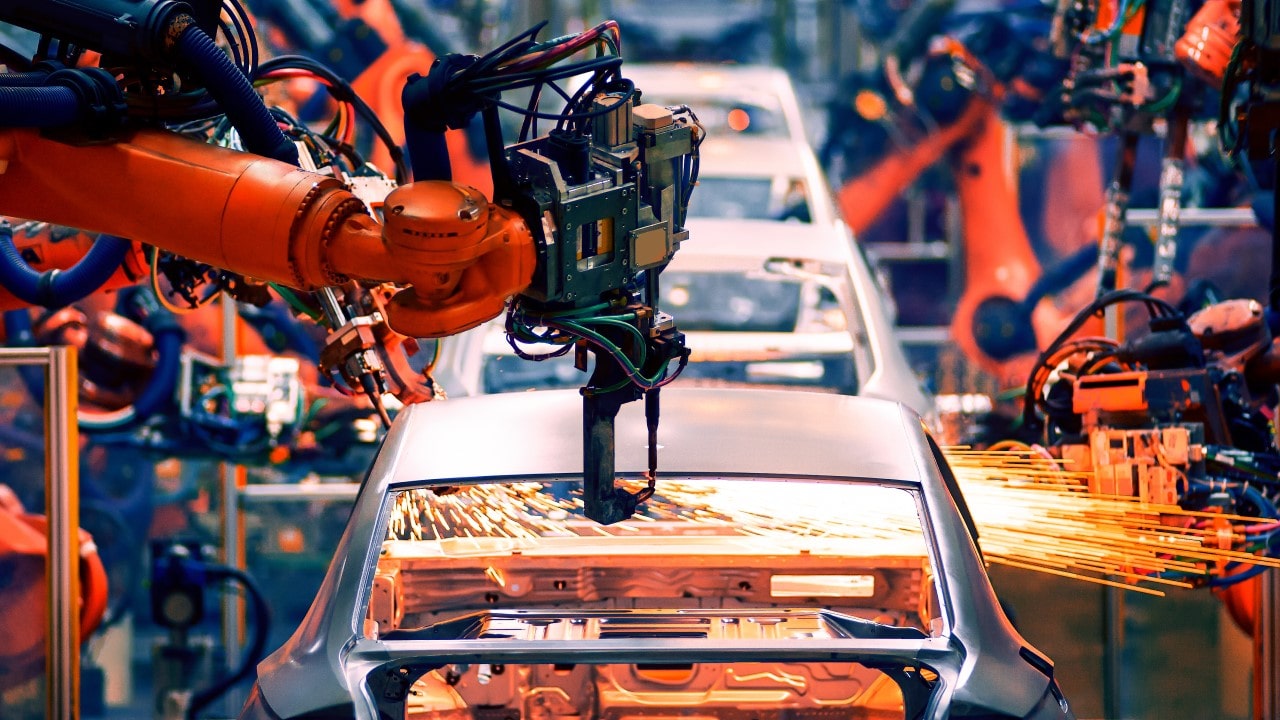

The automotive industry heavily relies on CNC machining for the production of engine parts, transmission systems, chassis components, and much more. CNC machining centers enable the precise cutting, shaping, and drilling of metal and composite materials used in vehicle manufacturing.

The automation and accuracy provided by CNC machining help ensure consistent quality, reduce errors, and optimize production efficiency.

Related: The Importance of Precision in CNC Machining →

In the aerospace industry, CNC machines play a crucial role in the fabrication of aircraft components and parts. From complex turbine blades to intricate structural elements, offer the precision required for aerospace manufacturing.

The ability to work with various materials, including aluminum, titanium, and composites, makes CNC machining indispensable in creating lightweight and high-strength aerospace components.

The medical industry relies on CNC machining for the production of medical devices, implants, and surgical instruments. CNC machines enable the creation of intricate and customized designs with exceptional accuracy, ensuring compatibility and functionality in medical applications.

From prosthetics to orthopedic implants, CNC machining centers help improve patient care by producing precise and reliable medical solutions.

The electronics industry benefits from CNC machining for the manufacturing of circuit boards, electronic components, and enclosures. CNC machines can accurately drill holes, cut traces, and shape intricate designs on printed circuit boards (PCBs).

This precision is essential for the miniaturization and complexity demanded by modern electronic devices. CNC machining also aids in the fabrication of casings and enclosures, providing the necessary accuracy for the assembly of electronic products.

In the furniture industry, CNC machining allows for the precise cutting, shaping, and carving of wood and other materials. CNC routers can create intricate designs and patterns, enabling the production of complex furniture pieces with detailed ornamentation. This technology enhances productivity and expands design possibilities, catering to both mass production and custom furniture manufacturing.

The jewelry industry uses CNC machining to create intricate and precise designs. CNC machines equipped with high-speed spindles and fine cutting tools can shape precious metals and gemstones with exceptional detail. This technology enables jewelers to bring complex designs to life and produce custom pieces efficiently.

The architectural industry also benefits from CNC machining in the fabrication of building components and decorative elements. CNC routers and milling machines can accurately cut, carve, and shape various materials like wood, stone, and aluminum. This enables the production of intricate architectural details, customized facades, and precision-fit components for construction projects.

Fadal is proud to serve as your trusted CNC machine builder in North America. To request an estimate or learn more about any of our CNC machines, please call (844) 323-2526. You may also fill out our online contact form and someone from our team will reach out to you soon.