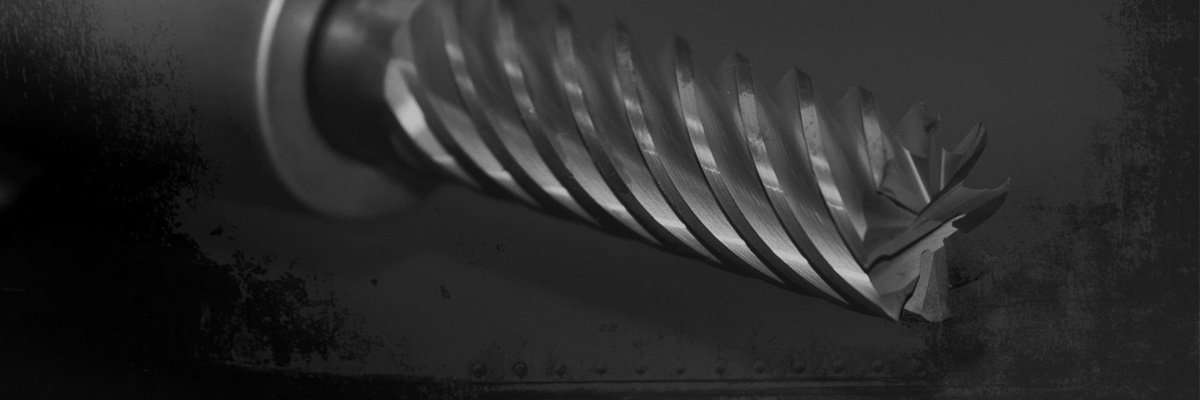

50 Years of Experience

Fadal is a CNC machine builder with dealers across the United States and Canada. Our clients have trusted us with their machining needs since 1973, and we’re proud to offer our lineup of Fadal machines for every industry and application imaginable.

Our CNC machining centers are easy to learn, simple to operate, and are built by our expert to last. Fadal is managed by people with over 100 years of combined experience in the machining, service, and applications for CNC machining.

Learn MoreWatch Video

More Than a Promise

2-Year Warranty

We stand behind what we build, and back that promise with the only 2-year/4,000 user-hour parts warranty and 1-year/2,000 user-hour labor warranty in the business that comes standard on every Fadal CNC machine and controller.*

Learn More

Steve E.

Steve E.

"Now that things have calmed (a little) I wanted to thank you for making this project a smooth and seemingly seamless process. Admittedly, going from the original 4020 choice to what we have affectionately named “Tha Beast” was a VERY thought filled decision. After all is said and done, I think we made the best decision for our company as I feel sure this opportunity to upgrade doesn’t. happen often and allows us to grow our capacity going forward.

JC is VERY good at his job, Very professional and eager to answer all question and help in all the ways he could. FADAL is very fortunate to have him on the “Team”

Barnhart Crane and Rigging was an Excellent choice for service they provided. Thank you for choosing them.

Thank you both , (and all involved) for making this as easy an endeavor as one could ask for.."

Steven M.

Steven M.

"It’s definitely been a journey and we’re very happy we made the decision to buy directly from Fadal. This experience has been pretty seemless and your reaction and delivery time was pretty awesome. The fact we have a machine making parts is a real testament to you and your team. Even in our hour of need, you didn’t take advantage of our position and helped us out. So thank you and we look forward to continuing this relationship with you."

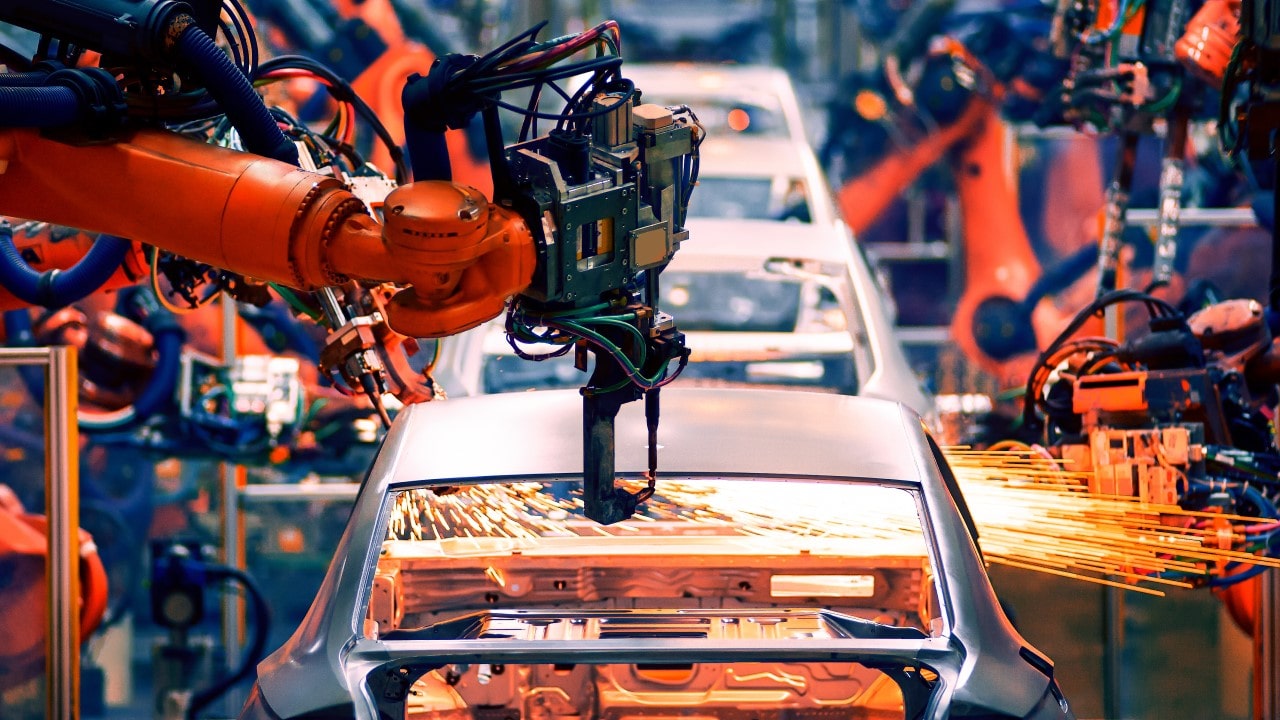

Industry Agnostic

From the Small Mom & Pop Shops to Major Manufacturing, We’ve Got the Right Machine For You

Every industry that requires precision machining—automotive, aerospace, medical, semiconductor, musical instruments, and many more. We work with them all providing high quality CNC machines that let you consistently deliver on-spec and on-time, no matter what you are manufacturing.

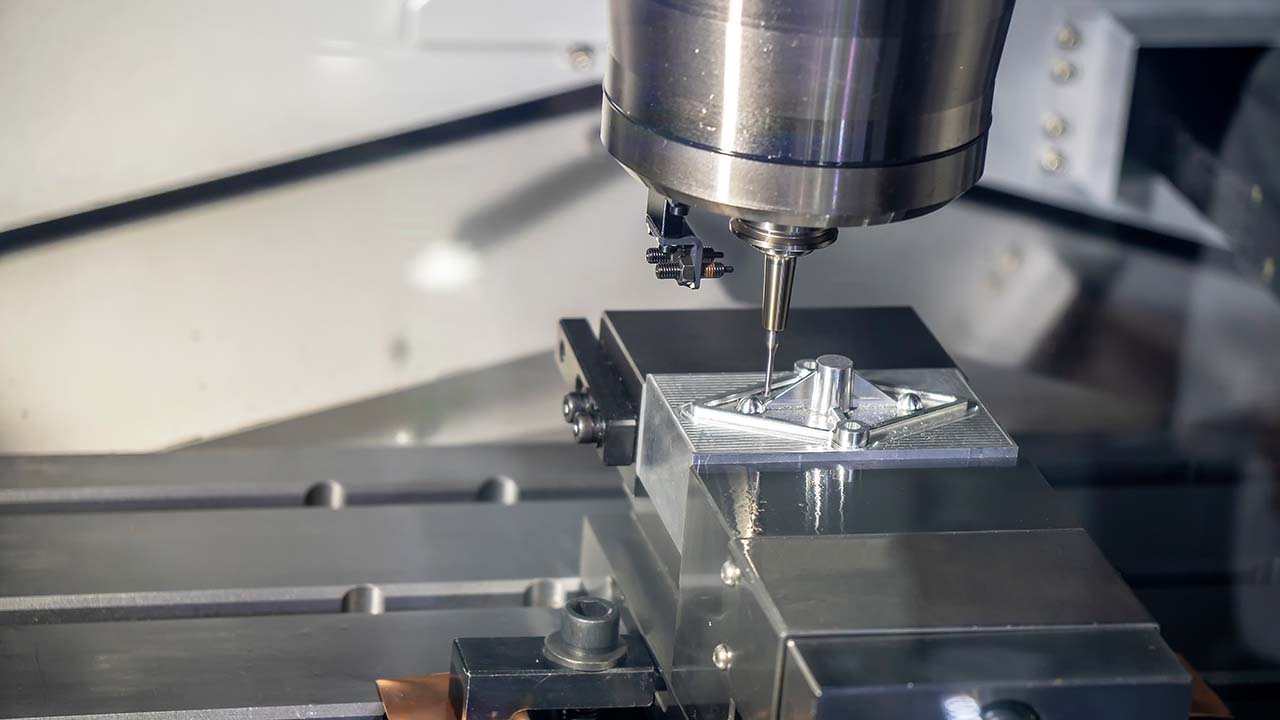

Production and Prototype

Set yourself apart from other —manufacture parts in shorter time frames, out of different material types and finishes with Fadal machines.

Die and Mold

Nearly all mass produced discrete parts are formed using production processes that employ dies and molds. Our CNC machining centers and controllers enable production of a large quantity of components made from steel or aluminum.

Machining

Ready to implement the latest technology in part and process design, rapid tooling, and optimized tool path generation for high speed cutting? Talk to Fadal, an American family-owned company.

Contact

Request a Quote

Start a conversation about how we can help you make the precision metal, plastic, graphite, REN Board, and wood parts that help shape our world.

Fadal

Blogs